UL 4128:2021 Medical Interconnect System Standard

Our complete waterproof connector series has passed 500 disinfection cycles using a 0.5% sodium hypochlorite solution with a contact resistance variation of ≤2mΩ, meeting the rigorous reliability demands of surgical equipment with frequent connections.

UL 2238 Industrial Equipment Connector Standard

Our waterproof connector series meets the stringent requirements of the US UL current cycling test (temperature rise ≤40K) and achieves a mechanical lifespan of over 25,000 mating cycles, ideal for photovoltaic inverters and heavy machinery applications.

CE LVD & EMC Directive Certification

Compliant with the EU Low Voltage Directive and EMC standards, our products ensure stable performance in the complex electromagnetic environments of Europe’s extensive railway networks.

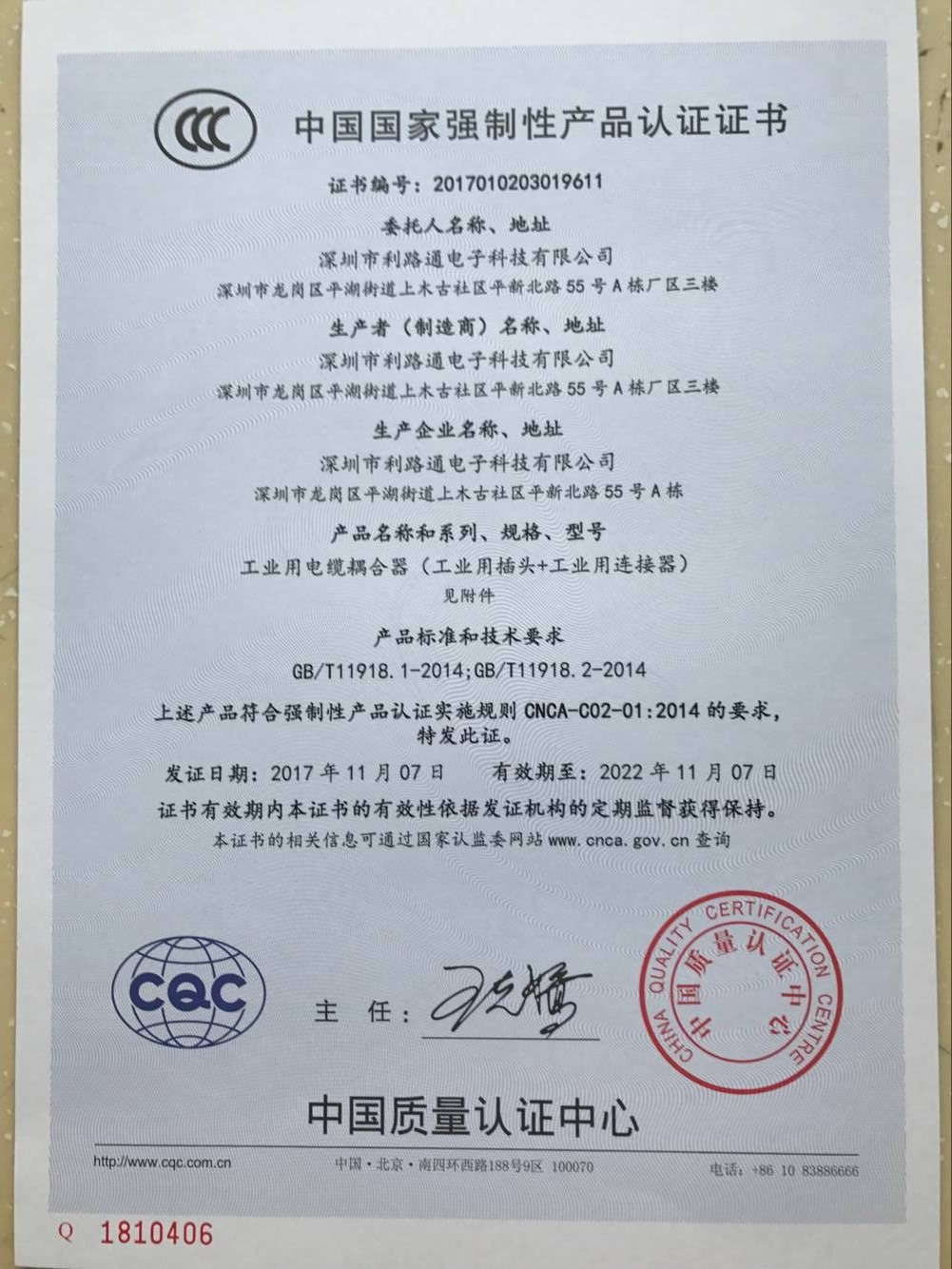

CCC (GB4943.1) Safety Certification

Having passed 32 rigorous tests, including abnormal temperature and insulation resistance checks, our products meet China’s stringent requirements for electrical safety and market entry.

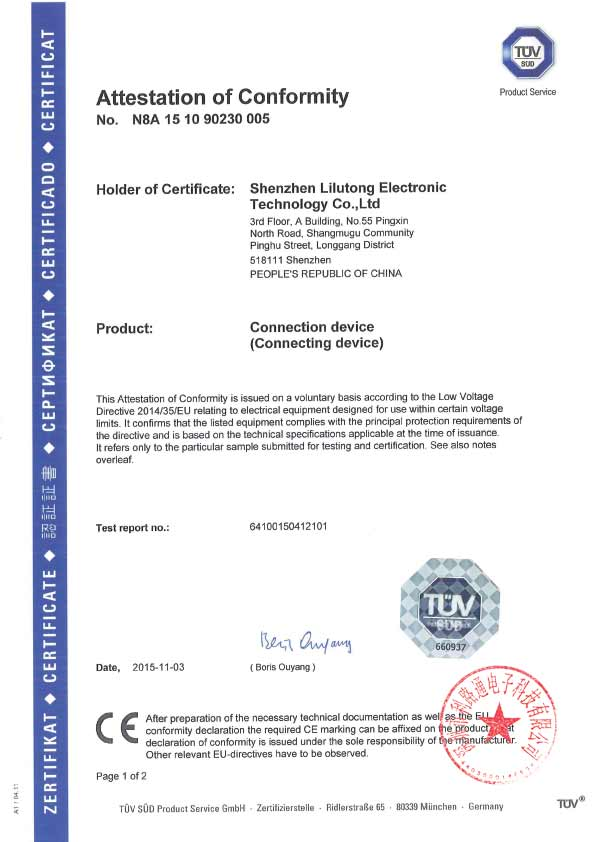

CE + TÜV Dual Certification

Exceeding EU electrical safety standards by 15% through supplementary testing by TÜV Rheinland, our connectors are optimized for industrial-grade export applications.

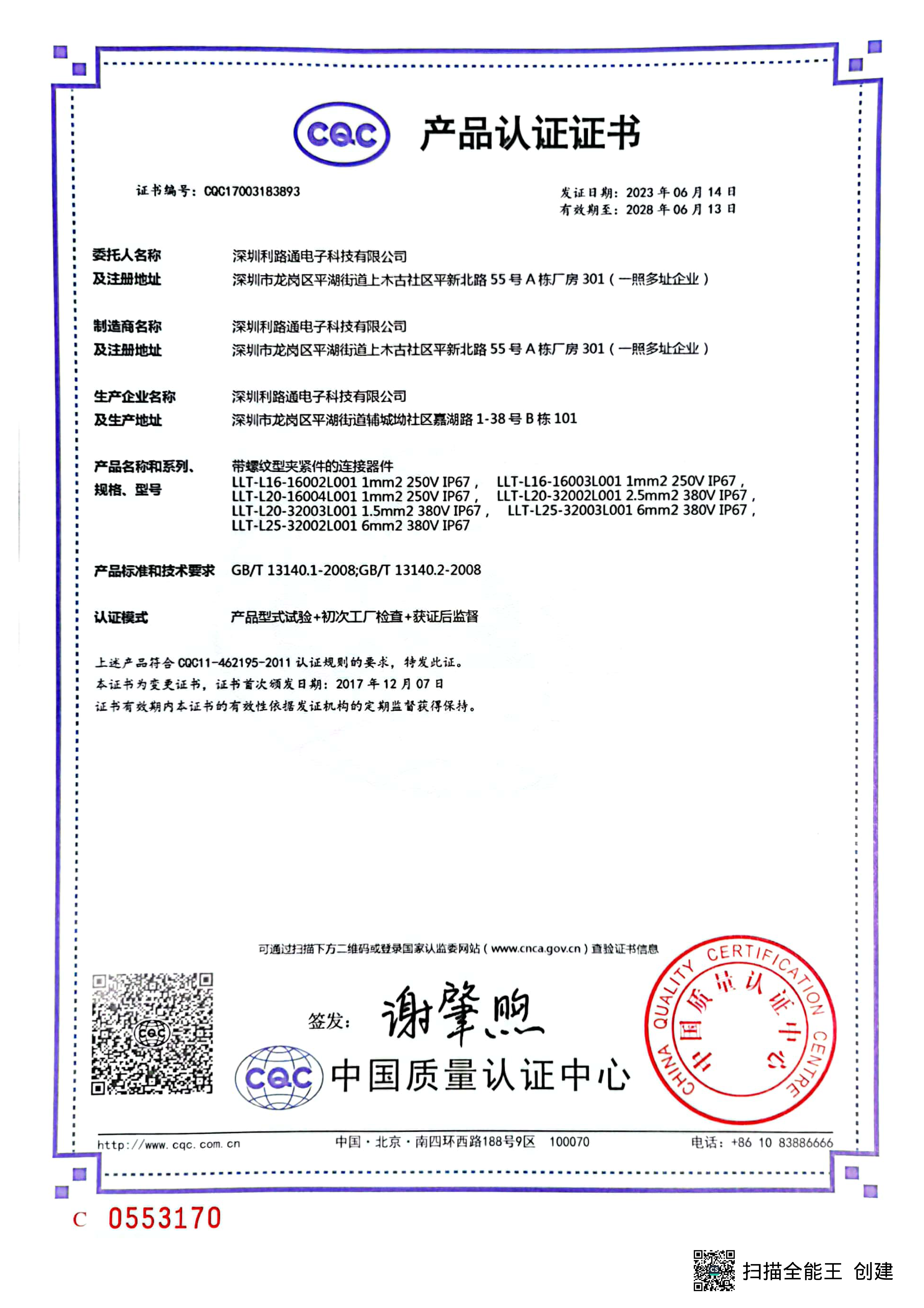

CQC Energy Efficiency & Environmental Certification

Conforming to the GB/T 23331 energy management system requirements with a standby power consumption ≤0.5W, empowering customers in building sustainable, green supply chains.

IATF 16949:2016 Automotive Quality Management

Ensuring PPM defects of ≤50 for automotive connectors, our products pass rigorous tests, including a 20G in-vehicle vibration impact and 96-hour salt spray tests, meeting industry quality standards.

IP68 Submersible Protection Certification

Engineered to perform under extreme conditions, our connectors have withstood a 30-minute immersion at 1-meter depth with dust ingress limited to ≤1mg/m³, ideal for underground mines and outdoor energy storage systems.

ISO 14001:2015 Environmental Management System

Our full range of waterproof connectors meets stringent ISO environmental standards, fulfilling the ESG certification requirements of global enterprises.

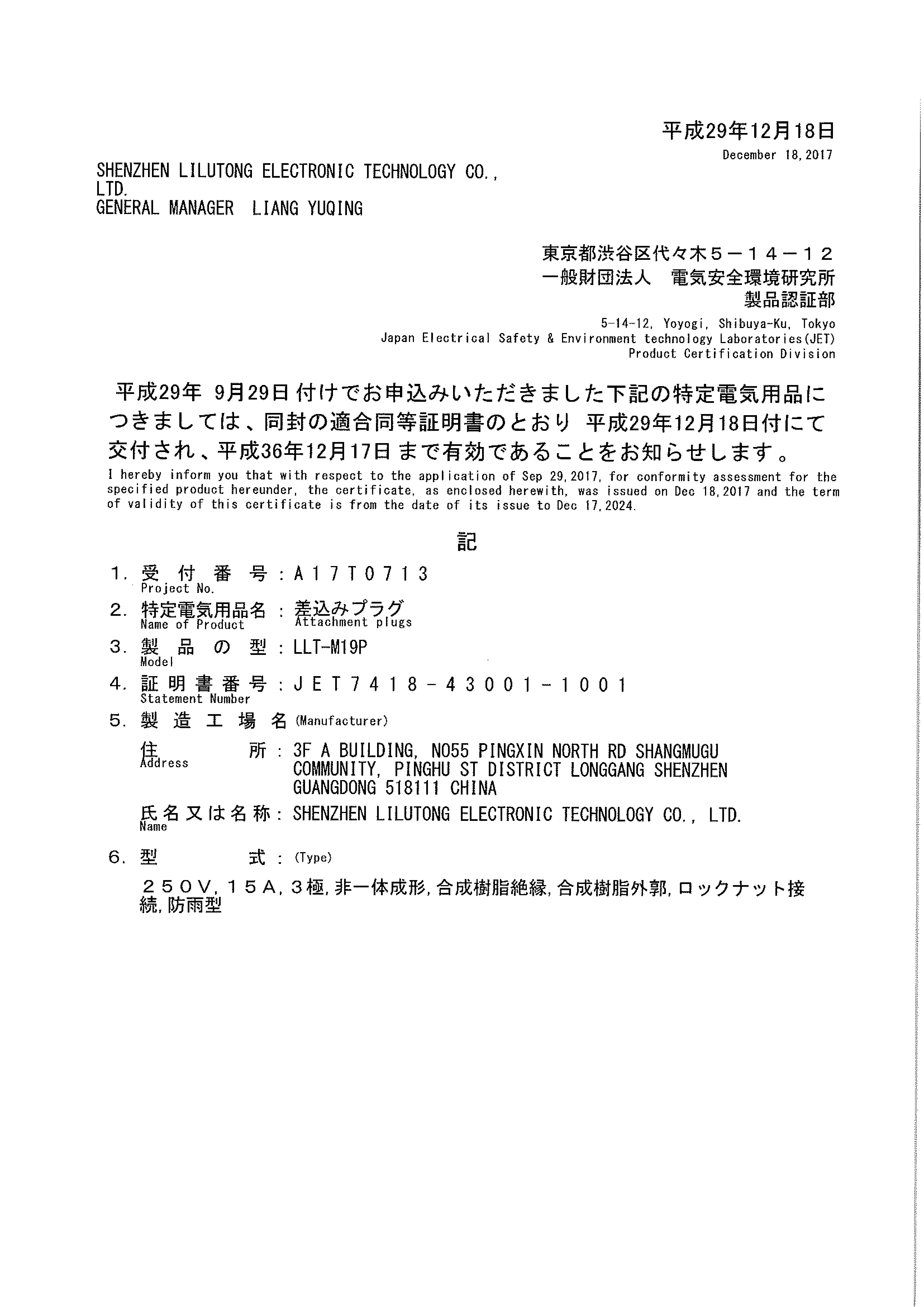

PSE (Diamond) Electrical Appliance Safety Certification

Meeting Japan’s strict electrical safety standards, our products have endured 1008 hours of high temperature (85°C) and humidity (85%) testing, ensuring reliable performance in saline and corrosive environments.

SAA AS/NZS 60335 Standard Certification

Our connectors have passed Australia’s creepage distance test (minimum 8mm) and achieved a V-1 flame rating, ensuring performance in environments with temperature fluctuations up to 60°C.

VDE 0620-1 Electrical Safety Certification

Our waterproof connector series meets rigorous durability standards for Germany’s Industry 4.0, passing a 150N mechanical strength test and a 3kV withstand voltage test.

TÜV Rheinland EMC Directive Certification

Complying with CISPR 32 Class B emission limits (30MHz-6GHz), our connectors ensure robust electromagnetic compatibility for 5G base station equipment.

National High-Tech Enterprise Certification

With over 200 connector patents (including inventions and utility models) and R&D investments exceeding 10%, our deep expertise in IP68 waterproof connector technology is industry acclaimed.

ISO 9001:2015 Quality Management System Certification

Our state-of-the-art SPC process control system (CpK ≥1.67) ensures precise management with connector terminal coplanarity maintained within ±0.05mm.